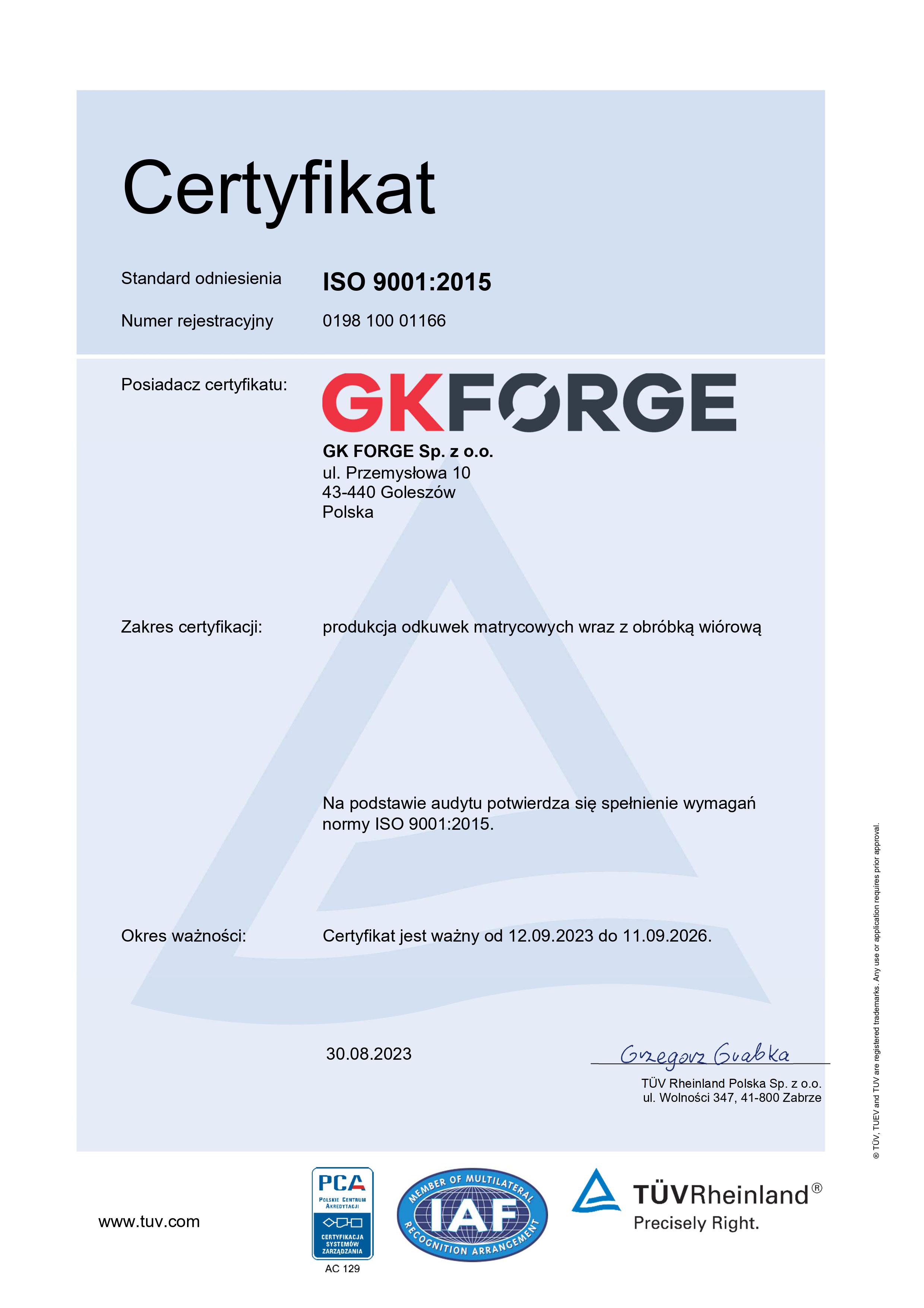

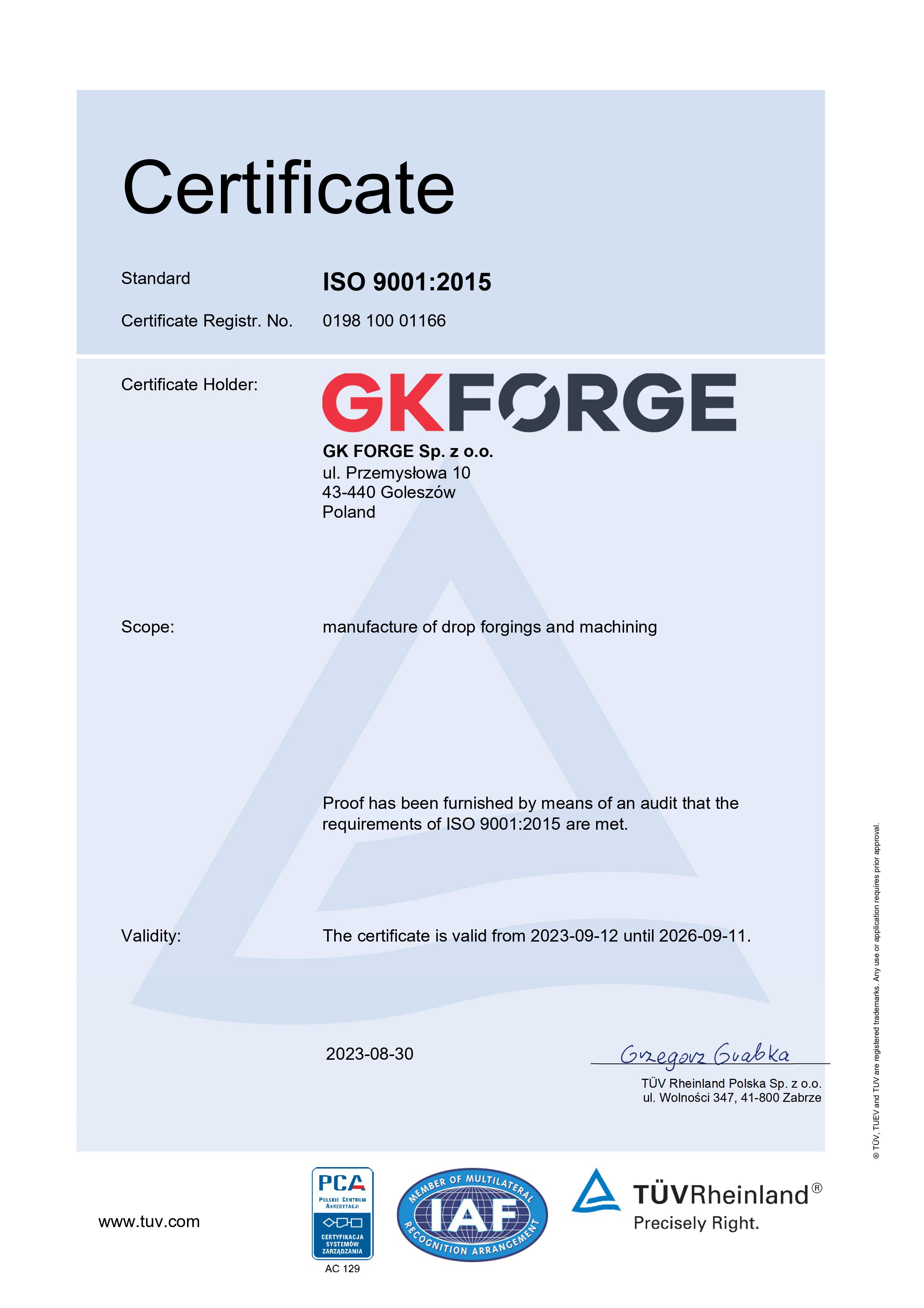

Quality System

GK FORGE Grelowski Obróbka Plastyczna Metali [Plastic Working of Metals] has the ISO 9001: 2015 Quality Management System Certificate in:

The production of die forgings including machining.

The main aim of the implemented Quality Policy is to produce and deliver products of quality meeting the customers’ requirements and expectations, while maintaining competitiveness and profitability of prices, with simultaneous protection of the natural environment and compliance with the sustainable development principles.

The organization places importance on interdisciplinary decision-making and group work, constantly striving to increase customer satisfaction and taking care of the interested parties’ needs.

The production process takes place under supervised conditions, starting from order acceptance, material delivery and throughout the production process up to the products release.

Product orders are always analysed in terms of the possibility to meet all customer requirements.

The following are developed for the manufactured products:

- flowchart,

- process FMEA,

- control plan - including delivery control, manufacture, products release, packaging and shipment.

Complete PPAP documentation - level 3, is provided for the first batches of products - patterns. Product control at individual production stages is carried out as part of auto-control and inter-operational control.

Factory quality control is aimed at verifying the degree of compliance with the Customers’ requirements in order to ensure the highest level of quality and safety of the offered products.

The organization has its own Factory Laboratory where the following tests are performed:

1. Measurements of geometric sizes using:

• coordinate measuring machine

• calibrated measuring tools

2. Mechanical properties tests including:

· hardness test using:

— Brinell method acc.to PN-EN ISO 6506-2 (HBW2.5/187.5)

— Vickers method acc.to PN-EN ISO 6507-1 (HV 5-30)

— Rockwell method acc.to PN-EN ISO 6508-1(HRC)

· Charpy impact tests acc. to PN-EN10045-1 (KV, KU)

· tensile tests acc. to PN-EN ISO 6892-1 (Re, Rm, A, Z).

Products ready for shipment are released by an authorized quality control employee.

Pursuant to our customers’ requirements, we accompany each delivery with acceptance certificates according to PN-EN ISO 10204:20006, type 3.1, confirming the workmanship compliance with the requirements specified in the customer's order. Our organization also produces forgings complying with the Pressure Equipment Directive (PED) 2014/68/EU. An acceptance certificate according to PN-EN ISO 10204:20006, type 3.2, is issued for each delivery and confirmed by a representative of the TÜV Rheinland Certification Body.