Forge

GK Forge core activity is the forge department. Thanks to our machine park, we can produce die forgings in the weight range from 0.05 to 7 kg, upset forgings in the diameter range from Ø8 to Ø40 and in the length range from 35mm to 12000mm. We produce forgings using carbon steel, alloy steel, stainless steel, acid-resistant steel as well as brass.

Learn moreForgings Machining

GKForge machine park makes it possible to perform low-volume machining of forgings on site, thus closing the chain from the design to finished workpiece. This allows for maximum simplification of logistics, thus shortening the process time, flexibility and speed of response to customer needs.

Learn moreTool Shop

GKFORGE tool shop department provides services using conventional machines such as CNC (Mikron, Mass, Okuma), surface grinders, lathes, milling machines, electric erosion machines. All machines in our Machine Park are operated by experienced and versatile staff, which ensures the highest quality of services.

Learn moreDepartments

GKFORGE has its own measurement laboratory where geometrical values are measured and mechanical properties tests are carried out. Our products are inspected at workstations and in the laboratory in accordance with the inspection plan. We accompany our products with material certificates and quality certificates according to EN 10204, type 3.1.

Learn more-

About Us

-

GKFORGE Company commenced its operations in 1983 as ZAKŁAD KUŹNICZY Karol Grelowski [Karol Grelowski FORGING PLANT]Since its establishment, the Company has been involved in the production of die forgings and open die forgings. Constantly implementing the development plan and expanding our production base, we work on the implementation of new technologies that guarantee high quality products. GK FORGE Grelowski company has over 30 years of experience in the production of forgings for the automotive, construction and gas industries as well as for the mechanical and agricultural sectors.

As a universal forge, we have a modern machine park comprising lines of presses with a pressing force ranging from 100 to 1600 tons and induction heating forging machines (1 to 3 inches). Thanks to these machines we can produce forgings weighing from 0.05 to 7 kg using steel of various grades such as e.g. carbon, alloy, stainless and acid-resistant steel as well as brass. Our entire production line is located in one plant, which allows us to shorten the production process to the minimum, and at the same time we can obtain repeatability and high quality products, while maintaining the workpiece prices at an attractive level. Our company can boast of short delivery times. We are able to start production within 3-4 weeks after the order placement date, and thanks to our extensive experience and modern equipment we can meet our customer requirements quickly.

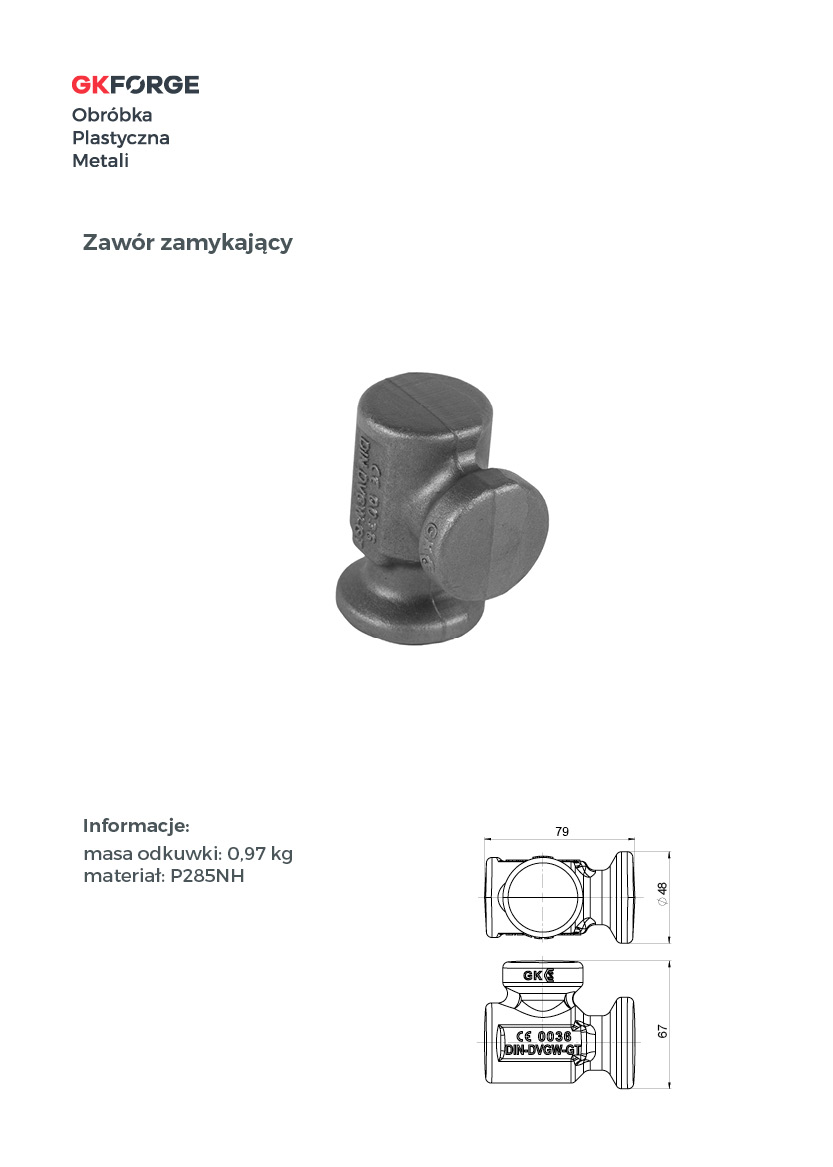

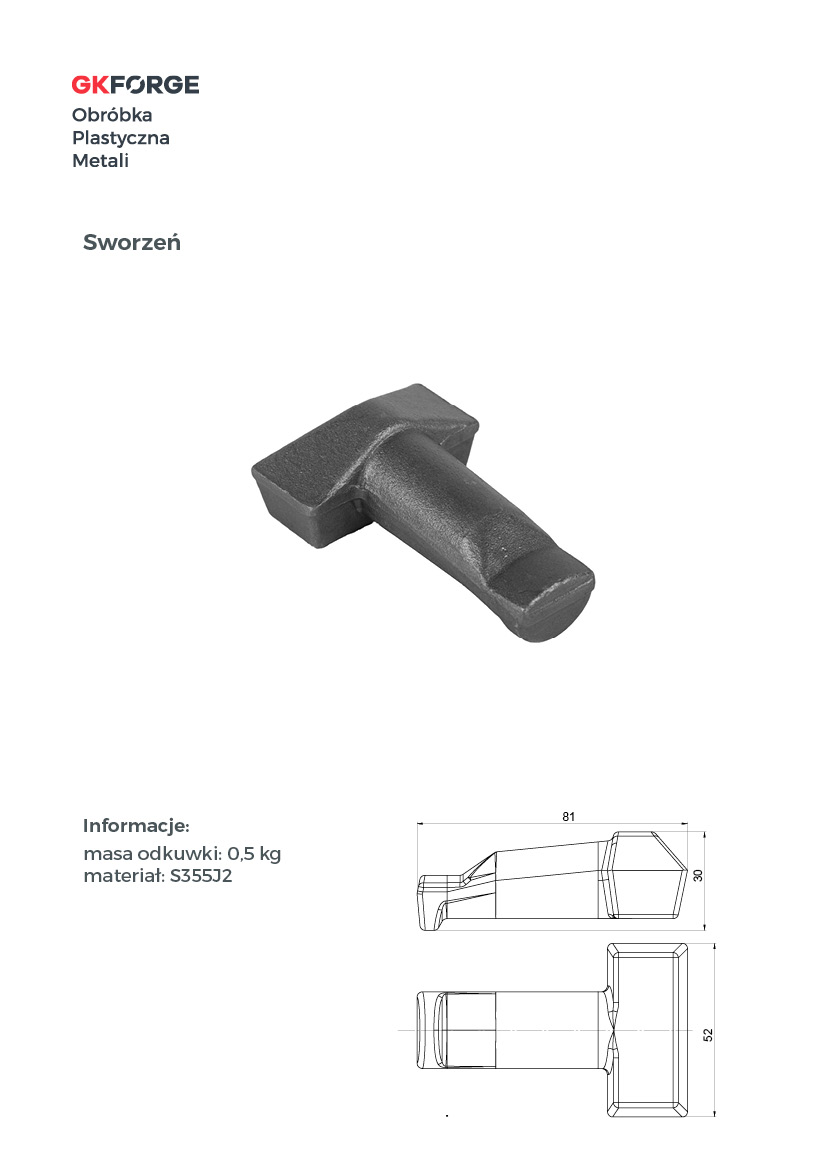

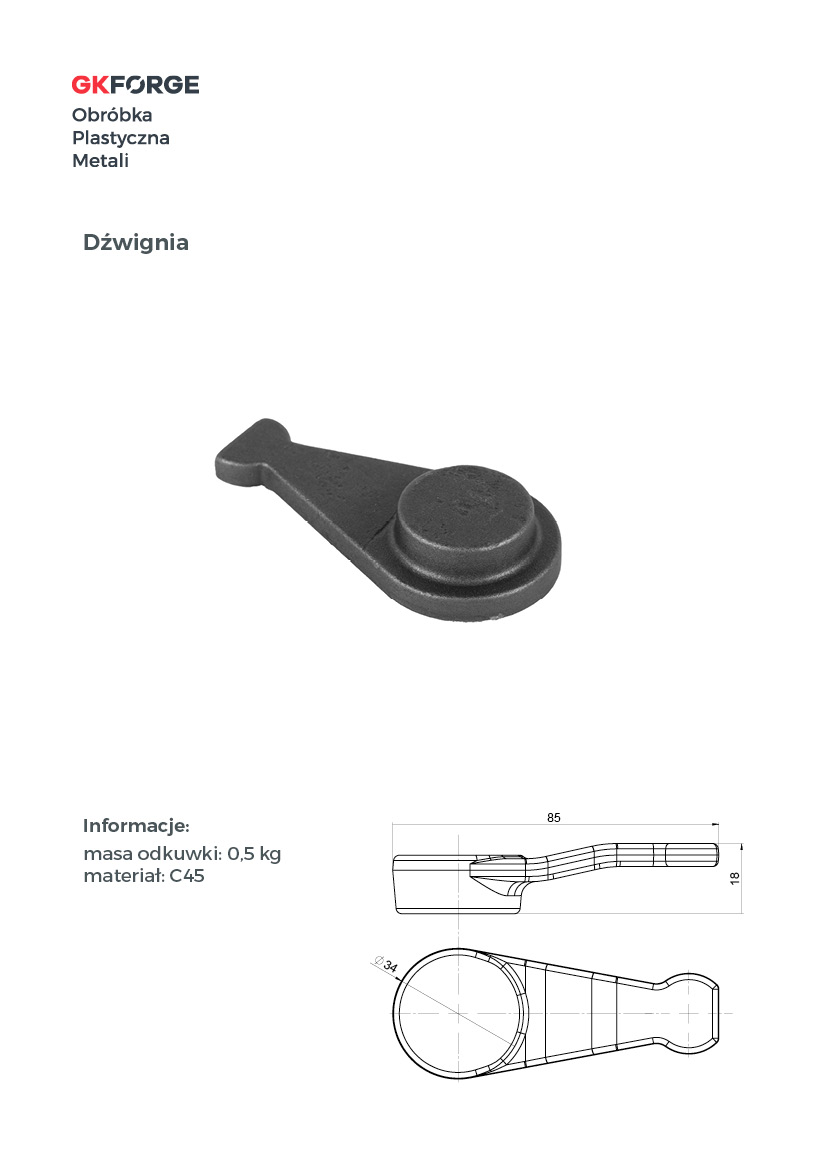

Selected products

See what products we can manufacture for you